Hello. This is Shinichi Manaka at Tokyo Electron Device America, Inc. (TEDAI). Hope you will enjoy our News & Blogs.

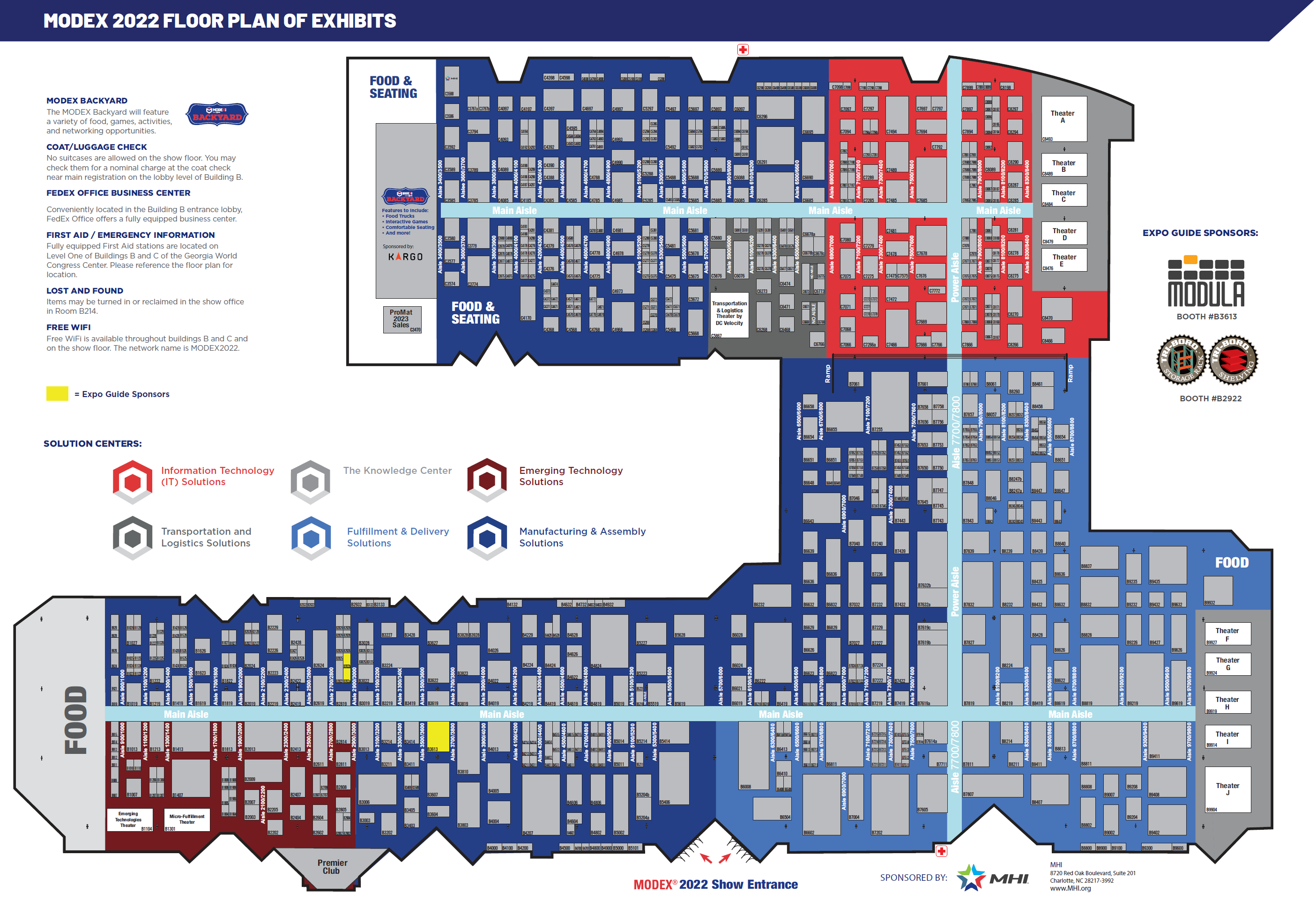

MODEX, organized by MHI, is one of the largest biennial trade show and conference in the U.S. for the material handling, supply chain, and logistics industries, and was held again this year at the World Congress Center in Atlanta, Georgia.

MHI, the organizer of MODEX, is a non-profit trade association representing the material handling, logistics and supply chain industries in the U.S. Founded in Pittsburgh in 1945, MHI’s 800+ corporate members are manufacturers of material handling, logistics and supply chain equipment, software developers, industry consultants, system integrators, and so force. The MHI hosts MODEX, which is held every two years in Atlanta, and they also host ProMat (with Automate, co-exhibited trade show with ProMat focusing on automation technologies and solutions), which is held every two years in Chicago, alternating with MODEX.

According to MHI, this year’s MODEX 2022 had a little over 37,000 attendees, which seems to be less than the 50,000 attendees two years ago, but I had the impression that the venue was quite crowded two years ago, especially during the first two days. Also, the number of exhibitors this year was a little over 850, slightly less than the 900 exhibitors two years ago, but considering the size of the venue, there was little difference from the previous show. Due to the impact of the pandemic, the number of participants from overseas is low, and most of them seem to be from North America this year.

The last time this event was held in March 2020, just before the pandemic, and I was surprised at the thoroughness of the disinfection at the venue, which was held in Atlanta, the home of the CDC, where masks were recommended but were always disinfected. The exhibition hall was about the size of Makuhari Messe’s 6 halls, with over 900 exhibitors, mainly from the U.S., and more than 150 seminar sessions. Food areas were set up in several areas within the exhibition hall, and in addition to the permanent stores, food trucks were set up and visitors were able to eat without leaving the exhibition hall, which is typical of the way exhibitions are held in the United States.

The most surprising thing I saw in the videos and photos of the MODEX 2022 venue was that most of the attendees were not wearing masks. The exhibition website has a section titled “Health & Safety” that explains guidelines from the U.S. Centers for Disease Control and Prevention (CDC), which strongly recommend that attendees wear masks. However, from the images of the exhibition hall and the keynote hall, I saw very few people wearing masks.

The videos and materials MHI made available during the event showed that while much attention was paid to technologies that will become mainstream in the next three to five years, there also seemed to be a focus on solutions that address the challenges of today and tomorrow in the supply chain. For example, WestRock, one of the largest providers of packaging solutions in the U.S. market, introduced a packaging material with an RFID label embedded in the box from the start.

The short video on RFID technology was also among the top 10 most viewed videos during MODEX 2022. The video introduces both active and passive RFID technologies in application-specific cases: “RFID Tags” (3:28)

Todd Farwell, Innovation Architect and Global Deployment Champion for Caterpillar Inc., discusses RFID tags and the potential they have for revealing insight into your supply chain.

During MODEX, keynotes are held every morning, but this year’s keynote focused more on human resources than technology, and the last keynote was given by former NBA player Shaquille O’Neal, which must have been very exciting:

- [3/28 Mon] Erika Alexander, Chief Global Operations Officer for Marriott International

- [3/29 Tue] Dr. Sanjay Gupta, Chief Medical Correspondent for CNN

- [3/30 Wed] “MHI Annual Report”, John Paxton and Thomas Boykin, MHI CEO | Deloitte

- [3/30 Wed] Shaquille O’Neal, NBA Hall of Famer

More than 170 free seminars were held in the seminar hall in the exhibition hall. The seminars were organized into seven tracks (numbers in parentheses indicate the number of sessions in each track):

- Transportation, Distribution and Warehousing (53)

- Manufacturing, Planning and Sourcing (3)

- Data Capture, Analytics, and Information Management (10)

- Automation & Robotics (80)

- Sustainability and Risk Management (4)

- Workforce and Labor (4)

- Emerging Supply Chain Technology (12)

One of the topics I look forward to at MODEX is the Innovation Awards. This year, the Innovation Awards were presented to the following three companies:

- Best New Products: “Remote Operation Platform Logistics”, Phantom Auto

- Founded in San Francisco in 2017, this software development venture focuses on tele-operation technology development. The company provides technology to safely and remotely operate forklifts, trucks, and other logistics service operations vehicles.

- Best IT Innovation: “On-Demand Labor Marketplace”, Veryable, Inc.

- Founded in 2016 in Dallas, Texas, this venture operates a marketplace for on-demand labor, primarily in the Mid-South U.S., to provide services for scaling up while securing labor in response to increased production and maintaining a constant cost structure.

- Best Innovation of an Existing Product: “Skateloader System”, Ancra Systems B.V.

- Dutch company that develops automated truck unloading and loading systems, primarily for shuttle service between production plants and distribution centers. It offers skate loader systems, carpet systems, chain/belt conveyor systems, and roller trucks.

I’m so excited that a venture here in the Bay Area has won the Innovation Awards.

This is my personal impression, but recently, AMR (Autonomous Mobile Robots) that move autonomously in warehouses tend to be deployed in combination with other automation solutions in warehouses or as a part of automation solutions. Tele-operation, in which a person operates a machine remotely, seems to be attracting more and more attention these days. Rather than always operating remotely, a kind of hybrid operation, in which autonomous operation is used when it is possible, and human operation is used when necessary, seems to be one solution that can be effective in a short period of time at this point.

The number of exhibitors this year was slightly lower than the previous year, at just over 850, due to the impact of COVID-19, but the number of exhibitors in each category was almost the same as the previous year (the numbers in parentheses indicate the number of exhibitors in each category):

- Attachments – Overhead & Lifting Equipment (32)

- Attachments – Trucks & Mobile Equipment (27)

- Automated Storage/Retrieval Systems (83)

- Automatic Guided Vehicle Systems (88)

- Automatic Identification Products (50)

- Autonomous Mobile Robots and Drones (82)

- Artificial Intelligence (53)

- Batteries/Chargers/Motors/Fuel/Alternative Fuel Systems (48)

- Below/Hook Equipment (i.e. sings; lifts; magnets) (6)

- Carousels (16)

- Casters, Wheels & Tires (18)

- Cleaning Systems & Equipment (14)

- Computer Hardware and/or Software (107)

- Consulting & Professional Services (84)

- Containers & Dunnage (29)

- Controls and Controlling Devices (58)

- Conveyors (99)

- Cranes (28)

- Decking & Flooring (22)

- Floor Trucks and Carts (38)

- Hand Lift Trucks (20)

- Hoists (11)

- Hydraulic & Electrical Components/Controls (25)

- Labels, Labeling Devices & Tracking Solutions (74)

- Lift Products (43)

- Lift Trucks, Personnel & Burden Carriers (38)

- Loading Dock Equipment (58)

- Mezzanines (34)

- Modular Drawer Storage (13)

- Monorails & Monorail Systems (22)

- Order Picking Fulfillment & Delivery (135)

- Packaging & Unitizing Machinery & Materials (60)

- Pallets & Palletizers ’73)

- Parcel, Freight & Cargo Distribution (40)

- Plant/Facility Equipment (98)

- Protective Guarding (39)

- Publications & Associations (7)

- Racks (55)

- Radio Frequency Identification & Data communications Equipment (49)

- Remote Control Equipment (16)

- Reverse Logistics Services (24)

- Robots, Industrial (97)

- Safety Equipment & Ergonomics (197)

- Scales & Weighting Equipment (18)

- Shelving, Workstations & Plant Furniture (39)

- Simulation Software & Services (38)

- Sortation Equipment (63)

- Supply Chain Execution Systems ’75)

- Supply Chain Security (27)

- Sustainable Facility/Recycling Equipment (17)

- Systems Integration Services (195)

- Transporation Providers (15)

- Third Party Logistics (32)

- Vertical Lift Module (27)

- Vertical Reciprocating Conveyors (16)

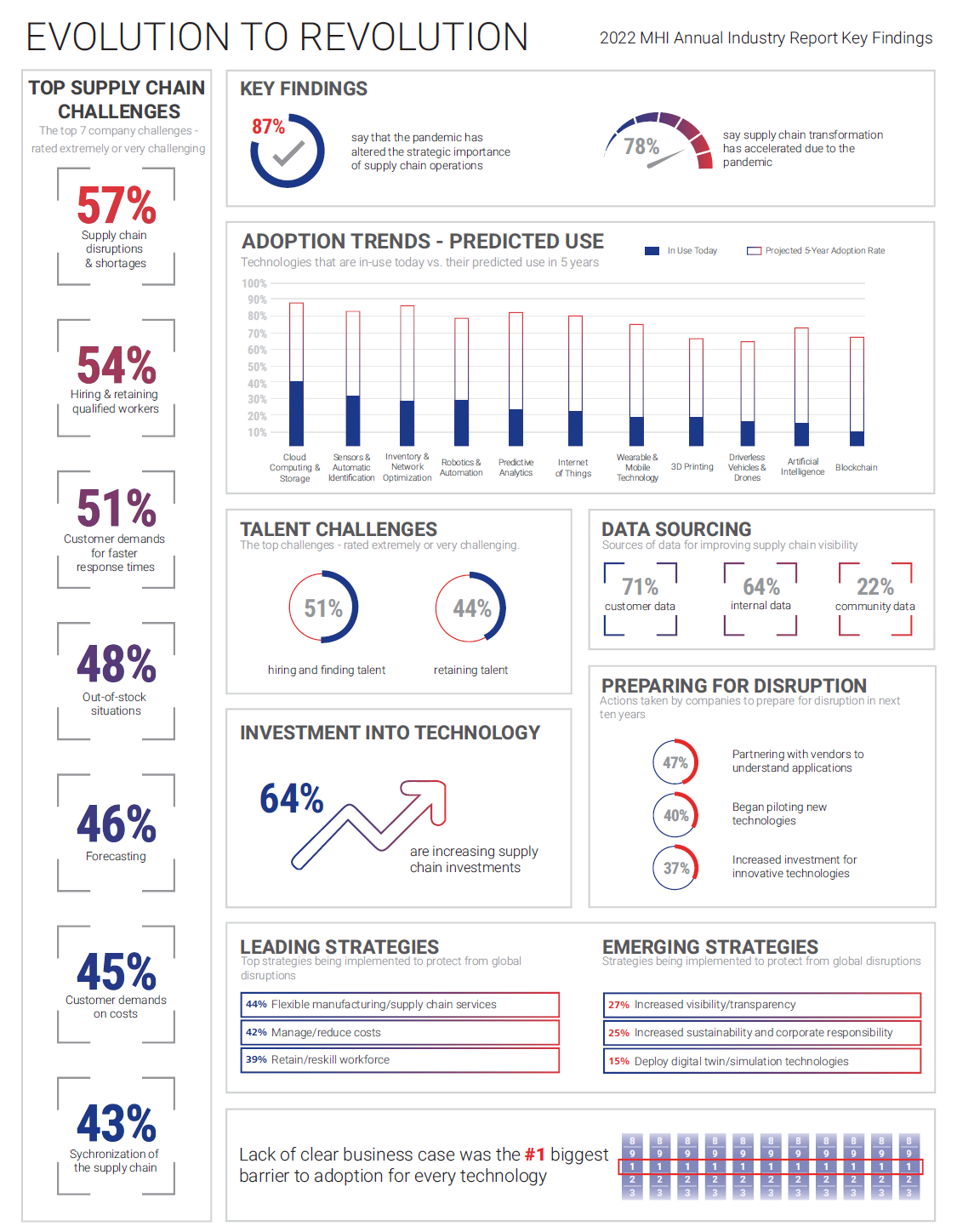

MHI CEO John Paxton and Deloitte analyst Thomas Boykin, who appeared as keynote speakers on the third day, reported on and discussed the “MHI Annual Report,” which has become a regular feature of the conference.

As you know, the supply chain industry has been severely impacted by the COVID-19 pandemic, and the “MHI Annual Report” presents the results of a survey of MHI member companies. The top challenges for the industry include maintaining supply chains, securing labor, and reducing logistics time. The labor force that was displaced by the pandemic has only returned to around 60% of its pre-pandemic level, and there seems to be an urgent need to address the expected increase in logistics volume.

The technical areas that received the most attention in the survey were:

- Industrial IoT (IIoT)

- Cloud Computing and Storage

- Blockchain and distributed ledger technology

- Robotics & Automation

- Wearable and mobile technologies

- Autonomous vehicles and drones

- 3D Printing (Additive Manufacturing)

- Predictive Analysis

- Inventory and network optimization tools

- AI Technology

It is interesting to note that the survey results show that the adoption of these technologies will more than double over the next five years, with cloud computing topping the list at 40% of companies that already have these technologies in place today, sensors and digital ID technologies such as RFID, voice recognition and bar codes at 31%, and inventory and network optimization tools at 28%.

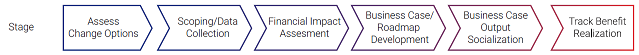

What is also interesting about the survey is that supply chain leaders cited the lack of a clear business case to justify the investment when adopting new technologies as their biggest challenge, and this is the biggest challenge not for any particular technology, but for all technologies.

Creating a business case is not easy, although the concept is not complex. When creating a business case, one must consider all the conditions and circumstances necessary to effectively execute all the steps in the process:

This is a brief report on MODEX 2022. I hope it will be of some help to you.